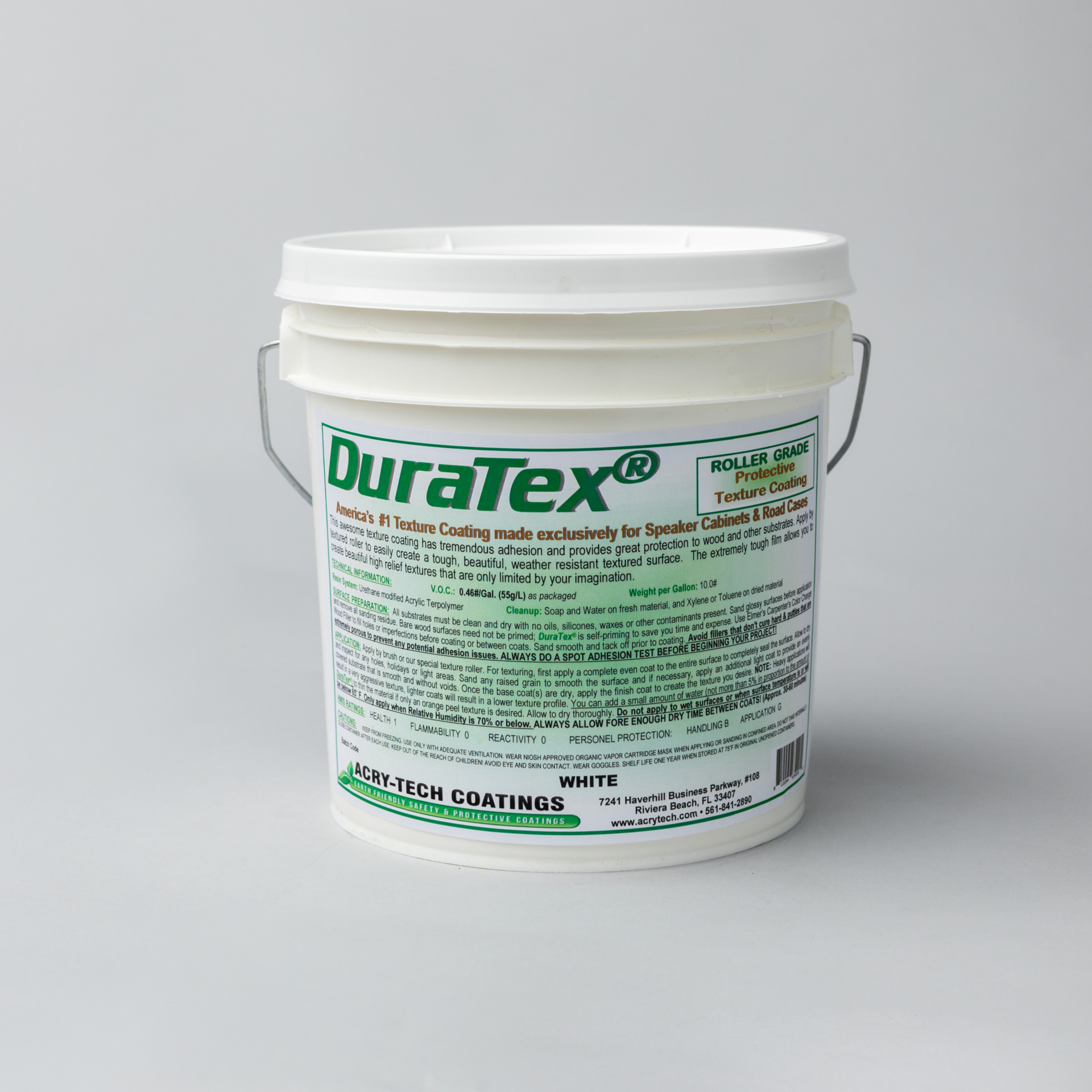

Speaker Cabinet Coating – DuraTex® Roller Grade: White

DuraTex® is America’s #1 Speaker Cabinet Coating, designed to provide beauty and protection to wood speaker cabinets and road cases. It’s a superior-performance Texture Coating that’s easy to apply, beautiful, and tough.

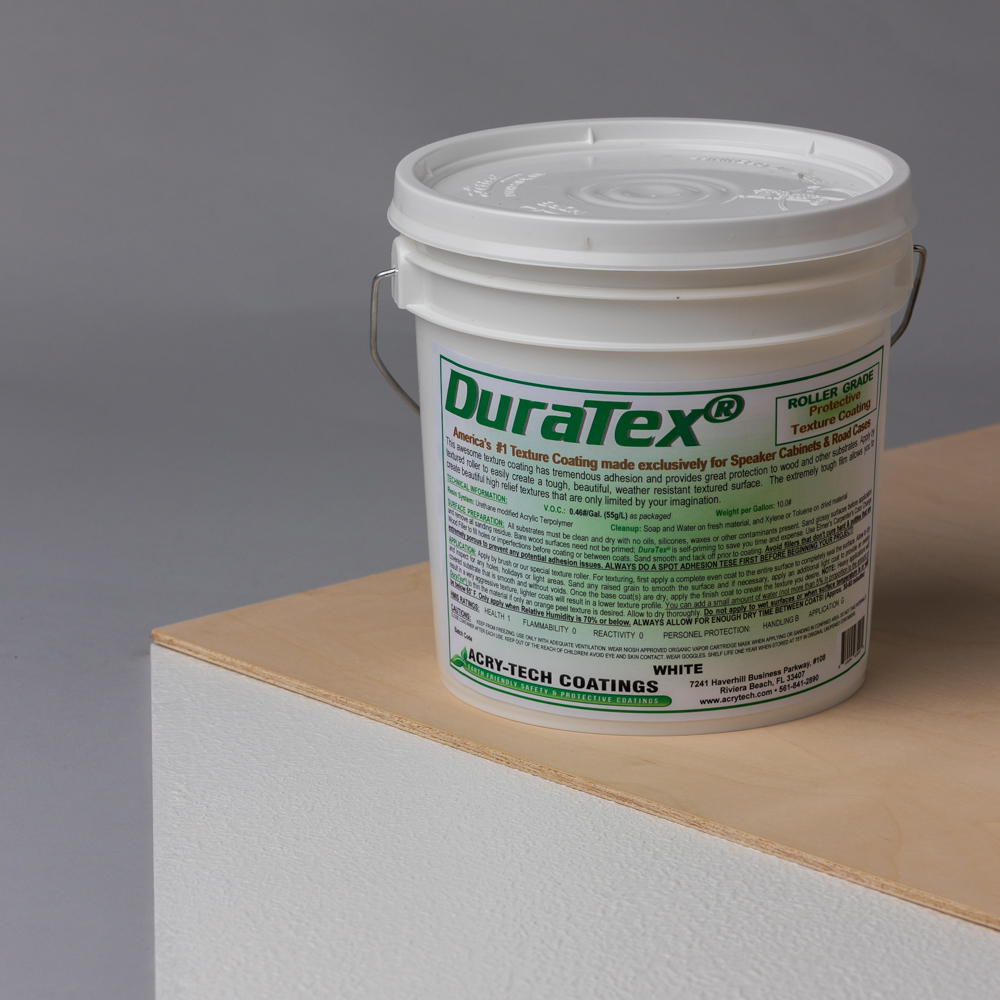

DuraTex® has tremendous adhesion to wood and other substrates. It rolls on easily with our special texture roller to create a tough, beautiful, weather-resistant, and easily maintained texture surface. For a smooth finish, apply with a smooth foam roller. DuraTex will cover up to 100 square feet per gallon in a two-coat application (or up to 200 square feet per gallon in a one-coat application).

DuraTex® is a blend of highly technical polymers and special LOW VOC coalescents that create beautiful, high-relief, durable textures. DuraTex® requires no special primers because it is self-priming.

Want to test drive this product before purchasing a gallon or more? Acry-Tech now offers a Trial Size Pint Can of white roller grade and a 3″ roller for $48.00 (including shipping). Check out our DuraTex™ Trial Size Kit that will give you enough DuraTex® to coat a couple of 12″ speaker cabs.

We’re also now offering White DuraTex® in a Quart Size, which comes with a 3″ roller, for $62.85 (including shipping in the USA). This size is perfect for projects that require more than the Pint-Size Kit but less than one gallon.

| Product |

SKU |

GTIN |

| 1 Gallon White Roller Grade |

DTRG-W-1 |

810094630089 |

| 5 Gallons White Roller Grade |

DTRG-W-5 |

810094630065 |

| 1 Gallon Black Roller Grade |

DTRG-B-1 |

810094630003 |

| 5 Gallons Black Roller Grade |

DTRG-B-5 |

810094630010 |

Technical Info

GENERAL INFORMATION:

DuraTex® is a high-performance protective texture coating with tremendous adhesion to wood and other substrates. DuraTex® requires no special primers and is easily applied with a brush or our textured foam roller to create a tough, beautiful, weather resistant and easily maintained texture surface. A smooth foam roller should be used if a smooth surface is desired. DuraTex® was designed to provide beauty and protection to wood speaker cabinets, road cases, flight cases and other applications. DuraTex® is a blend of highly technical polymers, and special LOW V.O.C coalescents for creating beautiful high relief spatter textures.

AVAILABLE IN:

Black or White, Spray or Roller Grade with Satin Finish

CUSTOM COLORS ARE ALSO AVAILABLE! CONTACT US FOR DETAILS.

TECHNICAL DATA (BLACK/WHITE):

- V.O.C.: 0.46#/Gal. (55g/L) as packaged

- Solids by Weight: 44% / 63%

- Solids by Volume: 40% / 51%

- Viscosity: Roller Grade=25Kcps, Spray Grade=15Kcps

- Wt per Gallon: 9.0# / 11.5#

- Cleanup: Soap and Water on fresh material, and Xylene or Toluene on dried material

SURFACE PREPARATION:

All substrates must be clean and dry with no oils, silicones, waxes or other contaminants. Fill holes in wood substrate with Elmer’s Carpenter’s Color Change Wood Filler to prevent potential adhesion issues. Stay away from certain wood fillers that stay soft & rubbery when they are fully cured because there is a chance that DuraTex may not adhere to these types of fillers. DO NOT USE A POROUS TYPE OF WOOD FILLER AS THESE COULD CAUSE POTENTIAL CRACKS IN THE DURATEX COATING. We recommend doing a spot adhesion test to ensure there are no issues with the DuraTex coating. Sand surfaces before application and remove all sanding residue. Bare wood surfaces need not be primed; however, a base coat of DuraTex® can be applied as its own primer. Please contact us with any questions.

APPLICATION:

Apply roller grade with our textured foam roller to evenly coat the surface if a textured surface is desired. A heavy first coat followed by a lighter second coat will give a milder texture. A heavy second coat will produce a more aggressive texture. Adding a small amount of water to the product will reduce the texture profile and can provide more of an orange peel texture. If a smooth finish is desired, use a smooth foam roller to apply and be mindful of any roller nap overlap marks.

Allow all materials to dry thoroughly through air drying or forced drying in a baking oven. Do not exceed temperatures of 150°F for drying. Heating speeds up the curing process of DuraTex® but normal air drying will accomplish the same finished result over time. (Oven heating is optional, but facilitates rapid production throughput.) Do not apply this product to damp surfaces or when surface temperature is or will be below 60°F. and when Relative Humidity is above 70%.

STORAGE:

To store containers that have been previously opened, spray a fine mist of water onto the coating surface in the container before resealing the lid. This raises humidity levels in the container and can help prevent the product drying or skinning over in the container.

HMIS RATINGS:

- HEALTH -1

- FLAMMABILITY – 0

- REACTIVITY – 0

- PERS. PROT.: HANDLING B

- APPLICATION G

CAUTIONS:

KEEP FROM FREEZING. USE ONLY WITH ADEQUATE VENTILATION. WEAR NIOSH APPROVED ORGANIC VAPOR CARTRIDGE MASK WHEN APPLYING OR SANDING IN CONFINED AREA. DO NOT TAKE INTERNALLY. CLOSE CONTAINER AFTER EACH USE. KEEP OUT OF THE REACH OF CHILDREN! AVOID EYE AND SKIN CONTACT. WEAR GOGGLES. SHELF LIFE AT LEAST ONE YEAR WHEN STORED AT 75°F IN ORIGINAL UNOPENED CONTAINERS.

Revised February 2021

Textures

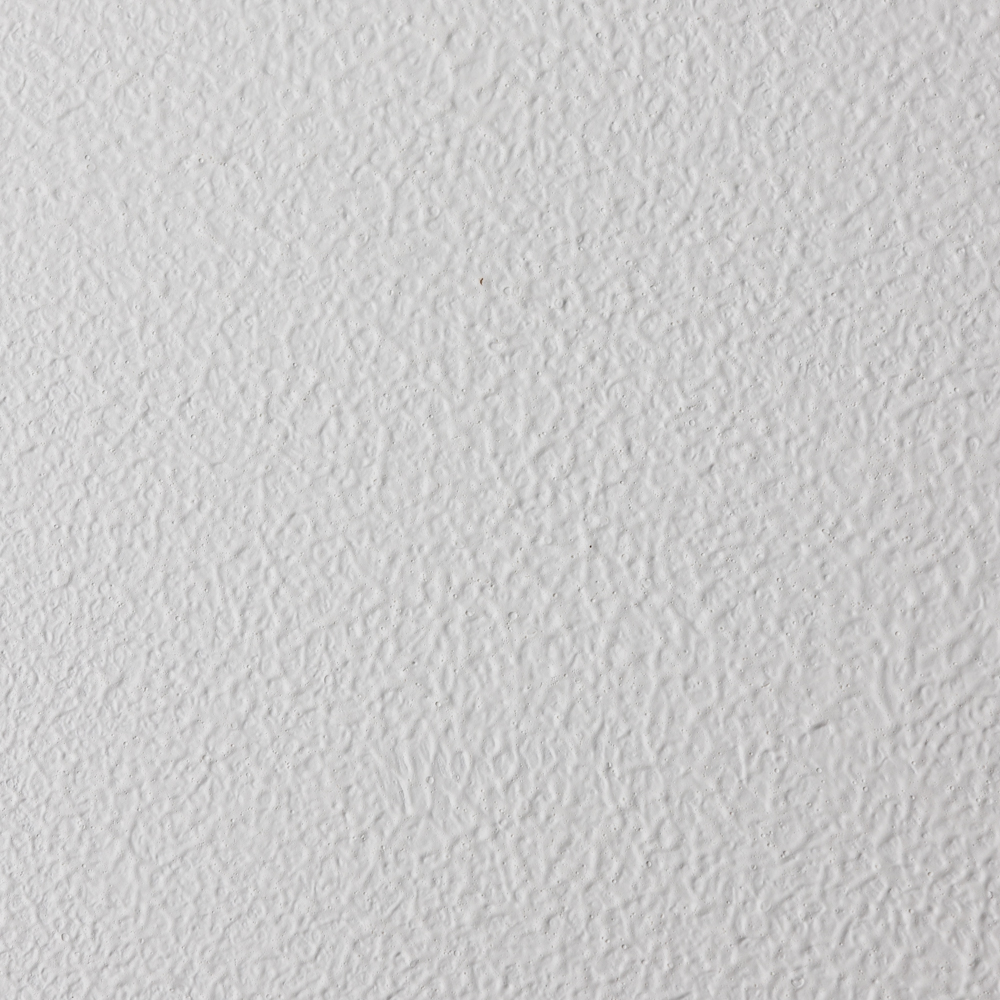

Textures created with DuraTex® include Fine Orange Peel, Heavy Orange Peel, Medium Orange Peel, Roller Grade Wild and Roller Grade.

Download PDF of Roller Grade Textures

Andy Pearson –

Great coating Replaced black carpet on a set of EV T221 cabinets for a church install.