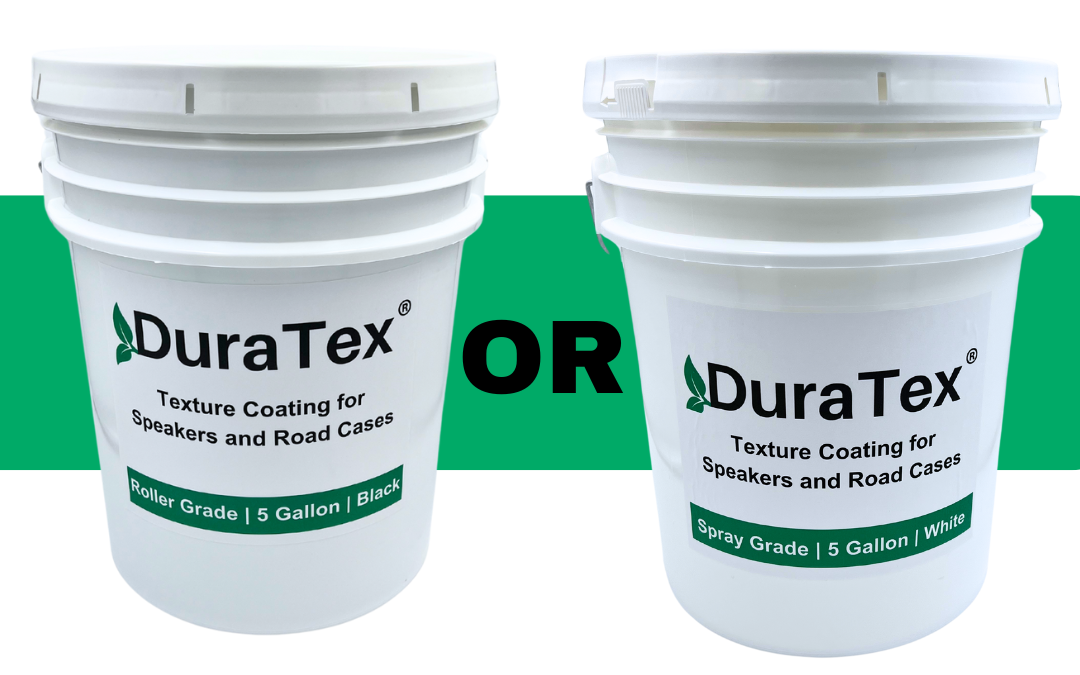

The Basics: Spray Grade vs. Roller Grade

DuraTex stands out for its exceptional quality and versatility regarding protective and decorative coatings. However, selecting the correct grade—spray or roller—can significantly impact the success of your project. Understanding the differences between these grades and choosing the right one is crucial, rather than attempting to dilute one to fit your needs.

Spray Grade DuraTex

- Application Method: The spray grade is designed to be applied using a spray gun and is ideal for achieving a smooth, even finish over large or intricate surfaces.

- Texture and Finish: This grade offers a finer texture, making it perfect for projects that desire a sleek, professional appearance.

- Drying Time: Faster drying times due to thinner application layers.

- Coverage: Efficient coverage with minimal waste, thanks to the controlled application.

Roller Grade DuraTex

- Application Method: Formulated for roller application, this grade is suited for smaller projects or surfaces where a thicker, textured finish is preferred.

- Texture and Finish: Provides a more pronounced texture, which can add a non-slip quality to surfaces, making it ideal for floors and decks.

- Drying Time: Slower drying times allow for more working time to achieve the desired texture.

- Coverage: Thicker application layers result in a more substantial protective coating.

Why It’s Important to Use the Right Grade

- Optimal Performance: Each grade of DuraTex is engineered to perform best with its intended application method. Using the spray grade with a roller, or vice versa, can compromise the coating’s performance and longevity.

- Consistent Finish: The finish and texture you achieve are directly related to using the correct grade. Diluting the product to make it suitable for an alternate application method can result in an inconsistent and unsatisfactory finish, impacting your project’s overall appearance and functionality.

- Material Integrity DuraTex products are formulated to meet specific viscosities and consistencies to ensure they adhere correctly and provide maximum protective qualities. Diluting the product can weaken its structural integrity, reducing its durability and protective capabilities.

- Ease of Application Each grade is designed to work seamlessly with its respective application tools. Using the wrong grade can make the application process more difficult, leading to potential issues such as uneven coverage, drips, or a patchy finish.

- Cost-Effectiveness While diluting a product to extend its use might seem cost-effective, this can actually lead to higher costs in the long run. An improperly applied coating may require additional materials and labor to correct, negating any initial savings.

By selecting the appropriate grade for your application, you ensure that your project meets your aesthetic expectations and stands up to the demands of use and time. For more information on DuraTex products and to find a suitable grade for your next project, visit our website or contact our knowledgeable team.

Call us at +1 561-841-2890 | [email protected]